date

stringlengths 10

10

| nb_tokens

int64 60

629k

| text_size

int64 234

1.02M

| content

stringlengths 234

1.02M

|

|---|---|---|---|

2018/08/08

| 656

| 2,853

|

<issue_start>username_0: Looking in the Cura interface, I can set any whole number 0-100 for the infill percentage. Does Cura have an algorithm to calculate a pattern for any of those possible values, or does it have a few patterns where it selects the closest one?<issue_comment>username_1: From what I can see, the only way to change the pattern is the manual way.

There is still an open gate to create a plugin that could select the pattern - but that is rather a complex solution - unless you will have a fully automated pipeline

Upvotes: 2 <issue_comment>username_2: There is a option for the infill pattern. It is one of the MAAAAANY by default hidden options in Cura. On the Header of the cathegories there will appear a gear symbol while hovering over the header. By klicking it a window will show up and provides this many options to be shown in the settings, if they were checked.

Upvotes: 2 <issue_comment>username_3: I fear I'm going to deny your question. The infil percentage and the infil pattern are two orthogonal properties, both of which contribute to the strength, density, mass, and print time of an object. Since there's no way for an algo to "know" what your desired outcome is, this can't be done.

Note - I used 'orthogonal' in the Hilbert sense, meaning neither property is a function of the other.

Upvotes: 3 <issue_comment>username_4: Infill serves two main purposes. These don't seem to map particularly well to the available controls.

**Adding strength to the part** The more plastic your part has inside, the stronger it will be. At least, that is the simplistic assumption. In fact, it seems that infill is not a particularly effective way of strengthening a part (compared for example with thicker walls and structural design features). What is apparent is that some infill patterns are stronger in certain directions, some are more isotropic, and some are just weak.

**Supporting upper layers** Without infill, any top faces on a model will involve bridging, so there is a trade-off between infill density, the number of top layers, and the quality of the top surface of your print. To reflect this function, slicers allow you to incrementally increase the infill density as you approach a top surface. This is particularly useful in a model that has a large inner void which does not otherwise need to be filled.

In addition to affecting the infill strength, adjusting the infill pattern can influence the points at which infill connects to the walls. For complex shapes this might affect how successful the print is. There are also other parameters which you can adjust (overlap, orientation).

The 'best' infill settings are influenced by the requirements of infill, and the 'success' metric does not appear to have a sharp response that would be useful in performing an optimisation.

Upvotes: 3 [selected_answer]

|

2018/08/08

| 882

| 2,813

|

<issue_start>username_0: I've just bought **Anycubic i3 Mega** printer and trying to level it.

So far I've printed test object and 2 others but looks like there are problems with leveling.

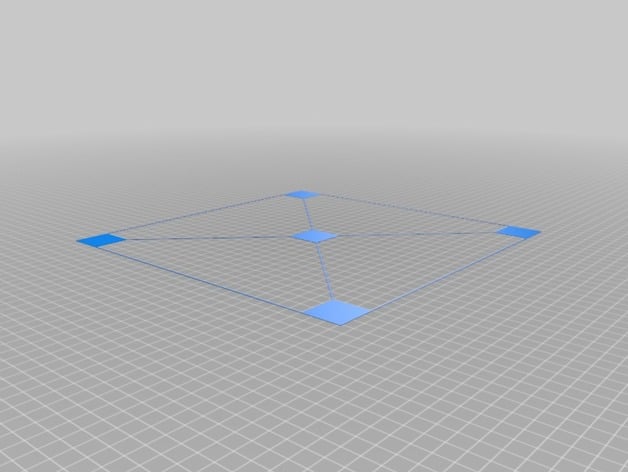

I want to make image of 5 small one layer squares(one in each corner and one in center). Looking for recommendations of **simple** software/tutorials/approaches to do it. I tried zbrush but found that it kind of complicated.<issue_comment>username_1: You are probably looking for something like [this](https://www.thingiverse.com/thing:2479352):

Note this is for large beds (300 x 300 mm), so you would have to X, Y scale this in your slicer.

This is a simple part that is very easily generated with [OpenSCAD](http://www.openscad.org) 3D design software (very good modeller if you are familiar with software coding), but could easily been designed in any [other tool](https://en.m.wikipedia.org/wiki/List_of_3D_modeling_software).

Another leveling and centering print that is created with OpenSCAD is [this](https://www.thingiverse.com/thing:2280529), and could be a start for you to create your own design:

[](https://i.stack.imgur.com/mH73a.jpg)

Note that the file with the design is located in the "files" section.

**Edit**:

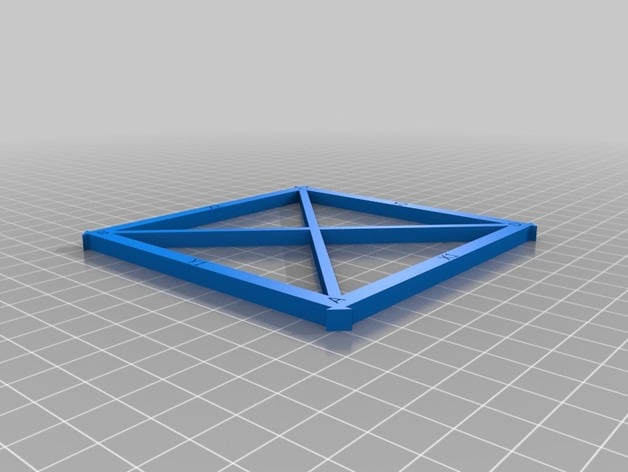

Some code for OpenSCAD made within 5 minutes (I don't type fast so it could have been faster if I did not use the constants, but if you go OpenSCAD, making parametric designs is almost a must ;) ):

```

// Set constants as you like

width = 30;

depth = 30;

layer_height = 0.2;

first_layer_height = 0.2;

nr_of_layers = 2;

box_size = 180;

// Calculated parameters

height = first_layer_height + (nr_of_layers - 1) * layer_height;

// Draw the test object

translate([-width/2, -depth/2,0]){

// Draw the center square

cube(size = [width, depth, height], center = false);

// Draw the corner squares

for (x=[-1:2:1]){

for (y=[-1:2:1]){

translate([x * (box_size-width)/2, y * (box_size-depth)/2, 0])

cube(size = [width, depth, height], center = false);

}

}

}

```

Rendered figure:

[](https://i.stack.imgur.com/bVNru.png)

Upvotes: 4 [selected_answer]<issue_comment>username_2: One of the most accessible modelling tools has to be [tinkercad](https://www.tinkercad.com/). Everything is done in the browser, and it even works (to an extent) on a tablet.

I wouldn't recommend getting too attached to it, since it is fairly limited. As an introduction to modeling in 3D, and some of the spatial concepts that you will need to get used to, it works very well.

Upvotes: 2

|

2018/08/08

| 747

| 2,789

|

<issue_start>username_0: I want to tackle an experiment with the following goal:

>

> Determine the correlations between printing parameters (temperatures,

> speeds, humidity, perimeters, infill, etc.) and tensile strength using

> a specific 3D printer, test specimen, and filament brand/model.

>

>

>

This goal calls for two parts then: a standardized **test procedure** and **test specimen**. For the test procedure, I've been asking myself:

>

> What portable, measurable and roughly consistent tensile strength test

> does not require building a complicated machine, can be performed with

> ready-made tools or machines available at a large hardware store, and

> can be set up within 5 minutes?

>

>

>

I am thinking here about a procedure that lies somewhere between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is defined, this begs the question:

>

> Is the ISO 3167 multipurpose test specimen an appropriate specimen for

> the test procedure outlined above or are there other specimens that

> are more suitable?

>

>

>

I was thinking that, since the usual filaments have an ultimate strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the "recoil" would be too much and one needs to use a smaller, weaker specimen.<issue_comment>username_1: For these kind of tests you could rely on the [ASTM](https://www.astm.org/) standards. They define test procedures and test specimen sizes for different types of tests. Or you can derive a specimen yourself based on these standards (e.g. for my bachelor's degree I used an alternative notch impact specimen as I was bound to the amount of available material of the turbine rotor blade the specimens were taken from). Considering the material, you could device up a contraption made from extrusion profiles or something.

Please do note that to get reasonable results, you would have to do a lot of tests as the spread in results is probably even more than in metals.

The company I work for does this, these material qualification programmes run for long times (years, as we also do fatigue and creep testing), and a lot of samples are tested to qualify for use in Aerospace applications.

Upvotes: 3 <issue_comment>username_2: A reliable and repeatable test can be performed by printing cylinders, tapping them to M4 thread and then testing the resulting bolts.

My Tech Fun

does something like that, but he prints the thread directly, which may be less repeatable.

Then you can perform pull and bend tests on the samples using simple attachments available at the hardware store.

Upvotes: 0

|

2018/08/09

| 1,663

| 5,382

|

<issue_start>username_0: I came across this suggestion on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce the stretching in the bowden tube you can add fiberglass packaging tape lengthwise along the tube. This would decrease the elasticity while still allowing the plastic filament to run through it. Allowing you to reduce the retraction length and have better control over the amount of plastic being extruded.

Is there any reasons that this would not work or actually decrease the performance of the bowden tube?<issue_comment>username_1: The question seems to be built on a false premise, namely that the major extrude/retract errors in a Bowden design come from tube stretch. The PTFE tube is *not* significantly elastic, actually it is reasonably stiff so there is minimal scope for improvement here.

A longer tube *will* contribute to degraded precision, but slack in the filament/tube gap is roughly as significant as stretch (and filament compression). Constraining the tube path may help marginally (but there is no need to 'bond' the tube). There is not much you can to to reduce the gap between filament and tube, but this will dominate the error for a long tube.

The most obvious weak point is the clip used to secure the tube at each end. I saw a review of a recent Prusa design where high quality clips were called out as making a big improvement to securing each end of the tube.

Upvotes: 4 [selected_answer]<issue_comment>username_2: The most common setup is 1.75 mm filament inside PTFE tube with 2 mm internal diameter and 4 mm outside diameter. The 4 mm outside diameter goes inside pneumatic push in 4 mm tube connector with 1/8 BSP thread that goes somewhere like E3D extruder.

It is very arguable if PTFE tube not significantly elastic. Apart from elasticity the filament some kind of compressing inside forming the sinus like line along the tube. And it has several places where it pushes at the tube wall and this deforms it slightly from circular to ellipse shape. All these effects accumulates with the length of the tube.

But in theory all these have minor effect if the feed rate is around the same value (the first order forces equalize and effect could be eliminated with proper retraction value). The bigger effect will be if feed rate changes and as result internal compression in the tube will vary and as result the melted filament will go out slightly off time. And this will affect quality but slightly and in some places of the print. Basically the motion variance will do some kind of coloring of the print.

I am personally recommend to use reinforced tube.

The best tube I found is 5 mm bike gear outer cable. It is steel reinforced with internal PTFE lining that perfectly suits 1.75 mm filament. Also it has outer layer of some kind of plastic that fit really well inside 5 mm push fit connector. The only problem is that 5 mm push fit connectors not common but you could find them on ebay as I did.

Another advantage of this cable is that you could cut out couple of centimetres of outer plastic at one end and the result steel shell will be 4 mm in diameter and goes deep inside E3D extruder.

The steel layer of this cable is actually spring and it makes this cable really perfect for 3D printer.

Upvotes: 2 <issue_comment>username_3: The [Young modulus](http://La%20solution%20propos%C3%A9e%20dans%20la%20revendication%201%20de%20la%20pr%C3%A9sente%20demande%20ne%20peut%20%C3%AAtre%20consid%C3%A9r%C3%A9e%20comme%20impliquant%20une%20activit%C3%A9%20inventive%20pour%20les%20motifs%20suivants:%2050%20Ohm%20repr%C3%A9sente%20la%20valeur%20ordinaire%20de%20l'imp%C3%A9dance%20des%20dispositifs%20de%20mesure,%20voir%20D3%20[alin%C3%A9a%2083].%20L'homme%20du%20m%C3%A9tier%20utiliserait%20cette%20valeur%20sans%20faire%20preuve%20d'esprit%20inventif.) of [PTFE](https://www.designerdata.nl/plastics/thermo+plastics/PTFE?cookie=YES) is about 500 MPa and the surface of a PTFE tube for 1.75 mm filament is about 9.4 mm2.

The Young modulus of [PLA](https://aip.scitation.org/doi/pdf/10.1063/1.4918424) is variable, between 350 and 2800 MPa, let's say 2000 MPa. The filament surface is 2.4 mm2.

The ratio is about 1 because the surface ratio is 4x and the Young's modulus ratio 1/4x. As result, the stretching of PTFE is about similar to the compression of PLA inside it (of course they sum, since they go in opposite directions). PLA is very stiff: other materials will compress much more and make the stretching of PTFE less relevant.

However the filament is thinner than the tube, so it will curl a bit, which increases its contraction much more! It is likely that even for PLA the stretching of the PTFE is much less relevant than the compression of the filament.

Anyway, [fiberglass](https://www.azom.com/properties.aspx?ArticleID=764) has a Young's modulus of about 80 GPa (150 times PTFE), but its thickness is what? 0.1 mm? That bring a surface of 2 mm2 at most (and I'm very optimistic, more likely much less than 1 mm2). Fiberglass helps to strengthen PTFE by a factor of surely less than 30, more likely 10 or less (will the glue hold or slide?).

As result, PTFE, from a contribution to the overall stretching/compression of 50 % (in fact, much less due to curling), will be reduced to about 5 %. It is good, but this is an optimistic value.

Upvotes: 1

|

2018/08/09

| 1,284

| 4,651

|

<issue_start>username_0: I think it's best that I explain what my issue is before I explain how I arrived here. I have a Tronxy x5s with a stock board that I am repairing for the sake of repairing, even though I know I should probably just spring for a new board. It's the principle of the thing.

* The extruder thermistor accurately reads for a few seconds, and then gives a negative reading as if it's been unplugged.

* I know that this is the same reading of an unplugged thermistor because when you unplug either the extruder or bed thermistor from a known-good port, it gives this same negative reading.

* It is not attached to the original pin. It is attached to a new pin that I moved it to. I cut the old pin off from the thermistor port and soldered the new pin to the traces of the port. Then I changed the pin in the configuration file, and it works, for a while.

* The electronics are messy but sound; I have used my voltmeter to verify connectivity and voltage.

* The thermistor works; it reads a little over 100kΩ in my hot garage and the temperature changes after I put it in my hand for a few minutes. But this temperature change only registers, as explained in the rest, for a few seconds.

* I am sure there's a configuration somewhere in the firmware that I am missing that causes that pin to either go "off" or become disused after a few seconds.

Greater context:

The printer was working great for months, but one day the extruder thermistor shorted so badly that the Analog to Digital pin on the Arduino powering the Melzi board was permanently damaged. The temperature reading consistently stayed at 260 °C, even when unplugged.

I wanted to come up with a repair solution rather than replacing the board (even though I have plans to do that anyway), so I downloaded the datasheet for the Arduino Mega 1248P and looked for other ADC pins I could use. I found that ADC Pin0 was unused on the board, so I thought I'd isolate old pin (ADC Pin 7), solder the trace to the new pin, and change the firmware to reflect the new pin.

[](https://i.stack.imgur.com/Nr4D2.jpg "Datasheet pinout")

[](https://i.stack.imgur.com/eUuyj.jpg "Photo of trace and isolation")

Then I changed the pin used for that extruder thermistor reading in the `Pins_SANGUINOLOLU_11.h` config file (the old Melzi board for the Tronxy X5s is a Sanguino):

```

// Temperature Sensors

//

#define TEMP_0_PIN 7 // Analog Input (pin 33 extruder)

#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)

```

Changed to

```

// Temperature Sensors

//

#define TEMP_0_PIN 0 // Analog Input (pin xx extruder)

#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)

```

I didn't know what "pin 33" was or used to be so I just put xx in the comment.

Anyway, my hardware was good, and my software was supposedly good, so I flashed the new firmware, plugged it in, and turned it on:

[](https://i.stack.imgur.com/xrAAq.jpg "Good temperature reading")

Yay! But after a few seconds...

[](https://i.stack.imgur.com/gbrNb.jpg "Bad temperature reading")

Boo. It stops working.

I am sure my connections are solid: I've tested for connectivity and voltage. Both the new port and the heat bed thermistor port get 4.97 volts, so it's not a voltage drop. It's something in the Arduino.

Any ideas?<issue_comment>username_1: Thermal expansion is opening a connection somewhere. It might not be one of your solderings, but if you shorted the board bad enough to fry pins, it could have cooked something somewhere else, and putting current through it is heating up the spot enough to break the connection. Either somewhere else in/on the board, or inside of the IC chip itself.

Upvotes: 1 <issue_comment>username_2: I am having the same issue so in the firmware instead of changing to an empty pin, I swapped pins 6 and 7 so the nozzle temp would read from the bed temp plug on the board. Now the nozzle temp is reading properly i went into configurations.h line 291 and changed the 1 to 999 and on line 295 i changed the value to 60 now the bed temp will always be 60 so as long as my print settings match it will never engage the heat bed and allow the machine to print. Now I will use an ESP8266 nodeMCU to read the temp and control the MOSFET for the heat bed.

Upvotes: 0

|

2018/08/10

| 659

| 2,487

|

<issue_start>username_0: I just received my new Creality Ender 3. I was going through and checking/adjusting everything for alignment, and I noticed that when you "auto home" the print head, the nozzle stops off the front of the print bed by 5-10 mm.

Is that normal?

Is it perhaps by design to allow purging the nozzle without dumping on the bed?

It doesn't appear that there is any way to adjust the Y stop switch without making modifications to it. It also didn't look like there was any easy way to move the bed either.<issue_comment>username_1: Yes, this is the "intended" behavior, as the home in relation to the physical limit position is not placed correctly about 7.5 mm into the bed in both X and Y.

to correct this, please look at the [Recalibrating Home-position](https://3dprinting.stackexchange.com/questions/6399/recalibrating-home-position) for the Ender3

Upvotes: 4 [selected_answer]<issue_comment>username_2: Many printer's X/Y endstops are not at the origin of the build plate/heated bed. In the firmware, an offset is defined from the build plate origin to the endstop locations. This is normal, nothing to worry about.

When you hook up your printer to your computer over USB, and install a program that can interface with the printer (e.g. PronterFace, OctoPrint, Repetier-Host, etc.) through a so called [terminal](https://3dprinting.stackexchange.com/questions/10573/what-is-a-printer-console-terminal?), you can send the print head to the origin with command `G1 X0 Y0` (or you can put that line in a G-code file and print the file, be sure to have homed the printer first with `G28`). You will then see the head move to the origin, which should normally be the left front corner as the firmware compensated for the endstop offsets. If the print head is not at the origin after these commands, you could recalibrate the [endstop offsets](https://3dprinting.stackexchange.com/questions/6375/how-to-center-my-prints-on-the-build-platform-re-calibrate-homing-offset/).

Upvotes: 3 <issue_comment>username_3: It is intentional for the head to start slightly off the build plate.

If it did start on the build plate you could crash the nozzle when the bed is not levelled. Note the level varies with temperature and build plate type. If you switch from PLA to ABS etc you should relevel the bed.

Having just had the innaccurate z-end stop switch cause a deep gouge across my stock build plate, I strongly recommend getting an ABL (auto bed leveller).

Upvotes: 2

|

2018/08/12

| 333

| 1,403

|

<issue_start>username_0: I bought a buddha statue and I would like to scan it using photogrammetry and publish the result.

**Am I allowed to do that?**

Is this the same like scanning a book and publishing it? Sketchfab on the other hand is full of 3d models of commercial products.<issue_comment>username_1: If the design was made from an artist and is not public domain, than you should not upload that scan without the (written) permission of the creator of the design. Espacially a scan of a decorative object will likely be protected, so costumers buy the original instead of printing itself or buy a printed version. If you would design a deco object and sell copies of it, you also don't want that others just scan it and print it.

Upvotes: 3 <issue_comment>username_2: First thing to do is get a lawyer skilled in copyright law as applicable where you live. It's going to depend in no small part on whether your scanned model is considered a copy or a transformative work of art.

Personally, I see scanning an object as similar to photographing it (or sketching it). Lots of art objects, or for that matter personal items such as a photo of a living person, are protected by copyright; others aren't. If I made the laws, which I sadly don't :-) , I would consider a scanned, printed object to be in the same boat as a sketch -- has to be demonstrably transformative and all that.

Upvotes: 2

|

2018/08/13

| 389

| 1,678

|

<issue_start>username_0: Cura has a layer view feature that lets you watch a simulation of the extruder head as it lays down material at each layer. Is it possible to get Cura to show a time stamp as it does this? That would let me set reminders to check a print just at certain critical times.<issue_comment>username_1: These estimates tend to be very approximate, even if Cura has the accurate acceleration values for your firmware. An error of 100% is not unusual.

What you probably want is an alarm at a specific layer (a few before the critical ones). You might be able to add this to Octoprint fairly easily - it does support plugins which can provide (for example) pushbullet notifications.

I'm not sure that 'critical' points are much more likely to fail than other less predictable things (like bed adheesion failure, extruder jams, filament breaks) - unless you're testing features (and then hopefully you can print only a slice of the part).

Upvotes: 3 <issue_comment>username_2: If I may interpret your question a bit, and add alternatives to <NAME>'s suggestions. I agree that any attempt to estimate elapsed time per layer is doomed.

Perhaps you should just look at the LayerView to determine the critical layers of interest. Then edit the gcode file in a text editor. Locate the start of the layer in question, and insert a PAUSE command (as well as whatever other actions your firmware supports, in case you can actually send an audible alarm or something).

If you really just want to print a subsection of the item, you're better off removing the unwanted parts in MeshMixer/MeshLab/whateverCAD , and slicing just the part you want to produce.

Upvotes: 2

|

2018/08/13

| 2,248

| 7,573

|

<issue_start>username_0: Creality does offer its firmware on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These are pretty good as backups as one can't alter and destroy them by accident.

But... How do you install them?!

---

This is about installing firmware *directly* and *without* another microcontroller. To use another mictrocontroller is [How to install new firmware via a Microcontroller?](https://3dprinting.stackexchange.com/questions/6685)<issue_comment>username_1: Creality also does provide an installation PDF. The process they propose is twofold and might need different settings on other machines1. Spots where I assume you might need to adjust are noted withA. Note that **this solution depends on CURA**.

1. Install the printer as a periphery machine.

----------------------------------------------

This part is specific for Windows. If you use Linux or a MAC, you will need to use a different setup, but you might get the same results.

1. Turn on the power on the printer and connect it from the MircoUSB to a USB of the computer. This should automatically install the driver. If not, the Driver is on the SD card provided with the Printer2.

* To manually install `windows Key` + "`MANAGER`" and choose *Device manager*. Find the serial port that shows yellow, Right-click, choose `Update driver software > Browse my computer for driver software`. Now `Browse`, find the location of USB driver on the SD card and click `Next`.

* Generally,the serial port(COM) you need update has the biggest number, but can change.

* A good idea is to confirm the correct port with a software like [Repetier Host](https://www.repetier.com/download-now/), with which you can control the printer directly - if it works, you got the drivers and the port correct. Also, you know the correct Baudrate.

2. After the driver installation, launch [CURA](https://ultimaker.com/en/products/ultimaker-cura-software) to do some settings. In `File > Preferences`:

* Print Window is "Pronterface UI"A

3. Switch to `Machine > Machine Settings`:

* Serial Port: choose the one that just was updated

* Baudrate: 115200A

2. Upload the .hex file via cura

--------------------------------

1. `Machine > Install custom Firmware`

2. Make sure the printer is connected, then `OK`

3. find the .hex file on your PC, then confirm.

4. Wait for the process to finish.

---

1 - most likely, you will have to change the baudrate

2 - This might not be true for all manufacturers, but is for creality. Other manufacturers might have different sources for these.

A - Adjust as needed!

Upvotes: 3 [selected_answer]<issue_comment>username_2: A major part of the Arduino IDE is sort of semi-hidden, and that is some guy called avrdude. Actually, [AVRDUDE – AVR Downloader/UploaDEr](https://www.nongnu.org/avrdude/) is a standalone binary.

As an aside, there is also `gcc` which does the compiling, but that is another matter. The `avrdude` uploads the compiled binary provided by `gcc` on to the Arduino, via the USB port (COM port).

You can invoke this from the command line (assuming that you have the Arduino IDE installed).

You will need to specify (see [command line option descriptions](https://www.nongnu.org/avrdude/user-manual/avrdude_4.html#Option-Descriptions)):

* The baud rate of the COM port (`-b`)

* The COM port (`-P`)

* The processor used in the board (for the Arduino Mega2560 board: ATmega2560) (`-p`)

* The path to the `.hex` file (`-U`)

* The path to the `.conf` file of avrdude itself (`-C`)

* Verbose mode, so see what is happening (`-v`)

* Specify the programmer to be used (`-c`). See the -c option on [command line option descriptions](https://www.nongnu.org/avrdude/user-manual/avrdude_4.html#Option-Descriptions) for more information.

* Disable auto erase for flash (`-D`)

The command will be of the form:

```

/hardware/tools/avr/bin/avrdude

-C/hardware/tools/avr/etc/avrdude.conf

-v -patmega2560 -carduino -b 115200 -cstk500v2

-P

-D -Uflash:w::i

```

This example above:

1. Specifies the full path to the `avrdude` binary

2. Specifies the full path to the `avrdude` `.conf` configuration file

3. Verbose mode

4. The ATmega2560 processor used in the Arduino Mega2560 board

5. The Arduino programmer

6. The baud rate of the USB port

7. The Atmel STK500 Version 2.x firmware programmer (may not be required)

8. The port to which the Arduino board is connected

9. Disables auto-flash as it is not required – Auto erase is not used for ATxmega devices as these devices can use page erase before writing each page so no explicit chip erase is required. Note however that any page not affected by the current operation will retain its previous contents.

10. The memory to be uploaded to and the path to the .hex file (see the -U option on [command line option descriptions](https://www.nongnu.org/avrdude/user-manual/avrdude_4.html#Option-Descriptions) for more information):

1. `flash` specifies the flash ROM of the device.

2. `w:` read the specified file and write it to the specified device memory

3. `:i` specifies Intel Hex

### Examples

For Windows

```

C:\dev\Arduino\hardware\tools\avr\bin\avrdude

-CC:\dev\Arduino\hardware\tools\avr\etc\avrdude.conf

-v -patmega2560 -carduino -b115200 -cstk500v2

-P\\.\COM1

-D -Uflash:w:C:\Users\\Documents\firmware.hex:i

```

For OSX

```

/Applications/Arduino/hardware/tools/avr/bin/avrdude

-C/Applications/Arduino/hardware/tools/avr/etc/avrdude.conf -v -patmega2560 -carduino -b115200 -cstk500v2 -P\\.\COM1 -D -Uflash:w:/Users//Documents/Arduino/firmware.hex:i

```

Alternatives

------------

If you are not comfortable using a command line interface (CLI) it might be easier to use a GUI solution…

### XLoader

For a Windows only solution, see [Uploading Arduino HEX files with XLoader](http://www.hobbytronics.co.uk/arduino-xloader)

[](https://i.stack.imgur.com/1Zglt.jpg "XLoader UI")

From the [author’s website](http://xloader.russemotto.com/):

>

> I’ve made a small program that can be used to upload your own \*.hex

> files to arduino boards using the bootloader. That means you don’t

> need a flash programmer. I made it for my own use and found it pretty

> useful. So now I’ve made a more user friendly version.. To use it

> compile you’re code in something like AvrStudio. Then simply start

> XLoader.exe, pick a hex file and press upload. That’s it. Good news it

> now also supports Arduino Uno.

>

>

>

### Arduino Builder

From [Arduino Builder – standalone utility for building and uploading Arduino sketches](http://arduinodev.com/arduino-uploader/)

>

> 1. Choose file, either a sketch file (.ino), an HEX file (.hex) or an ELF file (.elf)

> 2. Choose the board type in the dropdown list.

> 3. Click on the serial port (or USBASP button) and theuploading will be proceeded.

>

>

>

### Arduino Uploader

From the [same page](http://arduinodev.com/arduino-uploader/), there is Arduino Uploader which is a command line version of Arduino Builder.

Upvotes: 3 <issue_comment>username_3: The Prusa i3 MK3 comes with [Slic3r, Prusa Edition](https://www.prusa3d.com/slic3r-prusa-edition/). It has a menu for flashing the firmware, which takes a HEX file as input.

[](https://i.stack.imgur.com/L5TEH.png)

You can then select the HEX file. It will auto-detect the printer, if connected via USB.

[](https://i.stack.imgur.com/AQ9Lk.png)

Upvotes: 1

|

2018/08/13

| 1,155

| 3,903

|

<issue_start>username_0: Up till now, I've tended to scale my first layer according to the print quality, so a 0.12 mm first layer for a 0.08 mm print, and 0.28 mm for a 0.2 mm print.

After changing to a PLA which isn't sticking well, I'm wondering if the first layer is best determined by the printer/tolerance/material, rather than the overall print quality settings. Am I going to get more predictable results if I stick to a 0.12 mm first layer regardless? This is with a 0.4 mm nozzle on an Anet-A8.<issue_comment>username_1: Default settings for first layer height in Slic3r Prusa Edition print profiles regardless layer height is 0.2 mm.

If you need to improve bed adhesion then try tips from this video [3D Prints not sticking anymore? Watch this! 3DP101](https://www.youtube.com/watch?v=ShFaJ027pFs) by Maker's Muse. It's about using glue stick and spreading it using paper towel and isopropyl alcohol.

There are other possibilities how to improve bed adhesion, e.g. [Ultem sheet](https://shop.prusa3d.com/en/3d-printer-parts/146-replacement-pei-sheet-for-mk2s-ultem.html) or other printing surface like [BuildTak](https://www.buildtak.eu/).

Upvotes: 3 [selected_answer]<issue_comment>username_2: The first layer height can be the same as the whole printing model however you can set different sizes and speeds; it is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm *(if you are a master you can use higher dimensions)*

The first layer with a height of 0.3 mm with a speed of 70 mm/s will have less adhesion than printing at 50 mm/s. Also the same height and speed of 70 mm/s at 210 °C will have more adhesion than at 195 °C. So printing at 195 °C with speed of 50 mm/s could have the same adhesion than 70 mm/s at 210 °C. This depends on the quality of your PLA

On my prints I have set the prints at 195 °C and 55 mm/s with a height of 0.20 mm, then the whole print uses the same temperature at 85 mm/s with 0.25 mm of layer height. With other PLA quality I have to set 210 °C first layer at 50 mm/s, and other layers at 200 °C with 70 mm/s. ***So adjustments are based temperature and speed once you have determined the smoothness of your prints.***

Upvotes: 2 <issue_comment>username_3: I made more negative experience for 0.4 mm nozzle and 0.2 mm layer but 0.28 mm initial layer. Change it back to 0.2 mm solves all adhesion problems for me. (Tested on Anet A8 and Ultimaker3)

Upvotes: 1 <issue_comment>username_4: Layer height in my cura settings means that head of extruder will be going up at 0.3mmm, and how i know that? Because i measure few different settings with height of bed.

When I set bed to -0.2mm, ike everybody is proposing on internet, and i started printing first layer, I did stop it and measure with precise caliper thickness, it was 4.2mm, (human precision with leveling bed :P ) that was for me to much, because extruded material almost was not sticking to the bed,, and walls was not connected each other.

I did test also with home position of nozzle and setting bed to touch nozzle, to 0 height. ( YEAH) And again I measure thickness of first layer. It was precise 0.3mm. Exactly as I want.

That means that or I have better software witch can take nozzle up with initial layer in cura settings?, or magical printer, but my printer is cheap and is buy'ed almost by everybody.

That means that peoples who are teaching others how to set bed in a printer are totally wrong. Maybe no one measure thickens of first layer?

Even seller from who I buy printer propose me use paper with thickens of 0.25mm to set level of the bed.

Previously I have problems with first layer, because that was too high from bed, now when I set 0 position of nozzle exactly with bed, I don't have problems with thickens of layer, and printed element looks allot better from bottom.

Upvotes: 0

|

2018/08/13

| 899

| 2,745

|

<issue_start>username_0: I would love to start a small engraving business without having to purchase expensive hardware.

Using scrap parts at home, or parts from broken CD players, are there any ways to make a laser engraver at home? My cousin managed to make one of his own from scraps.<issue_comment>username_1: I have a printer and a diode laser head which will etch aluminum for under $4k, but you're going to have to manage potentially noxious fumes based on what material you're lasering. It's safe if used safely: the focal distance is 15-20mm from the lens, but all present should wear PPE.

Note: I work for Hyrel3D.

Upvotes: 1 <issue_comment>username_2: If you do not have knowledge about the electronics then consider buying a cheap etching machine instead.

Build

=====

Take a look on <https://hackaday.com/> and search for laser engravers.

I have found following articles in few seconds:

* [Hackaday.com: DVD LASER DIODE USED TO BUILD A LASER ENGRAVER](https://hackaday.com/2013/05/06/dvd-laser-diode-used-to-build-a-laser-engraver/)

* [Hackaday.com: LASER PCB EXPOSER BUILT FROM CD-ROM DRIVES](https://hackaday.com/2016/03/14/laser-pcb-exposer-built-from-cd-rom-drives/)

* [Hackaday.com: HOMEBUILT LASER ENGRAVER USING SALVAGED PARTS](https://hackaday.com/2017/10/31/homebuilt-laser-engraver-using-salvaged-parts/)

* [Hackaday.com: ENTRY-LEVEL 3D PRINTER BECOMES BUDGET PCB MACHINE](https://hackaday.com/2017/11/27/entry-level-3d-printer-becomes-budget-pcb-machine/)

Cheap laser engravers

=====================

And this one is about 2018 list of laser cutters/engravers: [15 Best Laser Cutters, Laser Engravers & AIO Machines of 2018](https://all3dp.com/1/best-home-desktop-laser-cutter-engraver-aio-machine/%20It%20lists%20machines%20around%20100$). It lists machines around 100$

* Meterk Laser Engraver ($125)

* NEJE DK-8-KZ ($70)

* QIILU Mini Laser Engraver ($130)

* SuperCarver K2 ($160)

Safety

======

Laser could damage your eyes (imagine laser reflection or if the machine falls from table when it's working). Take a look on [wikipedia](https://en.wikipedia.org/wiki/Laser_safety).

The best option is to use *acrylic cover* in same color as your laser, so you can observe the etching process and the laser beam is always blocked. For example take a look on orange cover of [Formlabs Form 2](https://formlabs.com/3d-printers/form-2/) 3d printer (it uses laser for printing).

Another protection is to wear *laser protection glasses*. Again the glasses must have same color as your laser.

Using laser for cutting or engraving means to burn material away. You should have good ventilation in the room.

Buy a *smoke detector* if you use cheap electronics with higher power consumption.

Upvotes: -1 [selected_answer]

|

2018/08/14

| 802

| 3,044

|

<issue_start>username_0: I got my Ender 3 a couple weeks ago. Within a couple days of test prints, I was able to get it working pretty well. Prints looked great. However, I installed [a more permanent solution to my X-Gantry binding issues](https://www.thingiverse.com/thing:2959991) and now print quality is down again.

[](https://i.stack.imgur.com/P5yjv.jpg)

The bottom .25" of the calibration part looks absolutely terrible, with hideous layer separation issues, while the upper .75" looks flawless. I have little idea what could be causing this issue.

[](https://i.stack.imgur.com/G5lab.jpg)

The only possible failure mode I can think of is that the bed isn't the right distance from the print head, but even fiddling with the knobs doesn't yield any better print quality than the print on the right of the first image. What can I do?

I slice with Cura and can make my profile available if it would be useful.<issue_comment>username_1: Well, you have several problems with your print. One that could be affecting your print is the nozzle temperature. The print looks wavy and has a lack of adhesion, so the filament is not flowing properly, causing under extrusion and will provoke a clogged nozzle.

Try to increase the temperature by 5°C and do a small test, don't wait to waste material and try another 2-3°C more.

Try to reduce the printing sped; try reducing the feed rate on your printer to 90% or less. While printing you can reduce the feed rate to see which speed works better at your printing temperature. I prefer to do this first rather than change the temperature; If you notice that your print gets better at lower feed rate *then* change your temperature higher to print a higher speed.

Upvotes: 2 <issue_comment>username_2: The answer now seems brain-dead obvious now. *Hindsight is 20/20, amirite?*

I had a decent filament clog in the extruder past the end of the Bowden tube. This was resolved by sticking a [nozzle cleaner rod](https://smile.amazon.com/dp/B078HXTLX8) up and down the filament path from the top of the extruder block several times and clearing the filament jam from the bottom of the Bowden tube. The printer works flawlessly now.

Upvotes: 3 [selected_answer]<issue_comment>username_3: I had a real problem with what I was poor bed adhesion and layer separation on my 6month old Ender 3 pro. this problem started all at once, I checked the bed height several times and layer height, temperatures etc still the problem was there.

Then I noticed the filament guide pinch roller was at a slight angle and on further inspection the plastic arm on removal was fractured so instead of holding the filament against the toothed drive it was metal to metal causing a slip on the nozzle feed.

I ordered a replacement aluminium feed roller kit at £6.99 the machine is working as it did when I first got it.

So it’s worth removing the pinch arm and inspecting.

Upvotes: 0

|

2018/08/16

| 900

| 3,107

|

<issue_start>username_0: I've been printing successfully on my CR-10 for the past year now. I've had issues now and then but have been able to look around the internet and solve them. I've been using some Flashforge white PLA with great results.

Example:

[](https://i.stack.imgur.com/JlMqb.jpg)

Last week I got a couple of new rolls of filament, black and orange. SinceI tried printing with them, I've got nothing but jams. The white prints fine, however.

[](https://i.stack.imgur.com/bC6Tt.jpg)

[](https://i.stack.imgur.com/5M8YN.jpg)

I dug around online and found this was happening to my printer: <https://www.youtube.com/watch?v=-vH_spN5wyw>

So yesterday I opened up my hotend to clean it out and got quite a bit of gunk out:

[](https://i.stack.imgur.com/MbatW.jpg)

I also changed my nozzle. I printed some with the old white PLA and printed fine. The moment I switched over to the new orange filament, it jammed after a few layers.

I ensured my nozzle was tightened and then got to measuring the filament. The older white one is 1.75mm in most places with some at 1.73mm.

The new ones that I got are pretty inconsistent - the orange one ranging from 1.68mm to 1.72mm; I found very few places where it was actually 1.75mm. The black one averaged 1.72mm.

So I made the change in my slicer but even then the first layer was visibly underextruding and it jammed soon after. I took apart the hotend and cleaned it out. Now, I put the white one back and its back printing fine.

Should I go ahead and return the filament?<issue_comment>username_1: Not all filaments are created equal. Even with the very same manufacturer, the addition of colorful pigments can change the needed printing temperature a lot! I have had a white china PLA that was giving ok quality at 200°C, but the same brand's clear PLA only took 195°C to print. My white Kaisertech prints better at the 200°C while orange needs a little more, something about 205°C - this is the same brand and manufacturer mind you. The matte "natural" PLA I have even needs some more heat, 210°C.

As a rule of thumb: **Printing temerature is filament dependant.** Test around (there are temperature tests - use them!) to find the ideal one for each brand and color combo you have.

It is also a goood idea to replace the claps on the Bowden tube, if the plugs appear more often.

Upvotes: 2 <issue_comment>username_2: From attached pictures I can see that some of the printouts are not sticking enough to the bed (that can be a non-leveled bed).

As you are printing directly on the glass ensure that the area is clean (no fat or other organic substances - clean with alcohol or another grease remover) or use a PVA glue to get better adhesion.

If the Z height is to low it can clog the nozzle, if to high then print will not stick.

Upvotes: 2

|

2018/08/22

| 2,148

| 8,488

|

<issue_start>username_0: Has anyone tried the steel-reinforced polyurethane timing belts? If so, how do they compare to the rubber ones?<issue_comment>username_1: I do not believe the standard rubber/plastic belts have any significant stretching over time, nor do they stretch under drive motor force during acceleration (and in any case, extrusion takes place mostly under steady-velocity conditions).

While I suppose it's possible a steel-reinforced belt might have a longer lifetime, replacing a belt is quick and cheap, so why bother?

*[incorporating comments]

My suspicion is that standard belts, e.g., as supplied with Prusa-clone kits will outlive us mere mortals. They can move an entire print bed+heater, so a larger print head is not an issue.*

The usual problem with any belt material is ensuring there's no significant slack (which leads to backlash/hysteresis), and changing the material won't help or hurt tensioning control systems.

Upvotes: 1 <issue_comment>username_2: Belts come in several formulations. This [page](https://www.mcmaster.com/#belts/=1e9qsqj) from McMaster-Carr lists several types of belts. The main materials (rubbers) are Neoprene and urethane, with fiberglass, Kevlar, and steel reinforcement. I would suggest spending some time looking at these, comparing the specs, and basing your choice on the needs of your application.

I used 1/4" wide MXL series cut-to-length in my machine. I have yet to see a wear or stretch problem and haven't yet done the high-speed photography to look for dynamic stretch. IMO, I have a bigger problem with the length of belt resonating like a guitar string than I do with the stretch of the belt. The compliance needed for resonance can come not only from the belt but also from the mechanical system it is mounted to. In some cases, a slightly stretchy belt could dampen oscillations that would otherwise result from impulse forces being coupled into the printer frame.

Upvotes: 3 <issue_comment>username_3: It's a question of **what you want to use the belt for.**

All Belts are subject to stress as they run around the motor and idlers and gears and bend. They will get eaten as they are subject to friction against parts, they will stretch as they are subject to tension. All this applies some sort of stress or another on the belt. Anything that is subject to stress wears. And as it wears, it will fail. The question is just: **What is your life expectancy?** The lifetime expectancy is again dependant on how the belt is used, so usage dictates lifetime of the belt.

Each belt type has an application it is designed for. A bending radius that is to be kept at, a gear it is to be used with, a load it is expected to move, a tension it is expected to uphold, and a lifetime it is expected to serve.

Let's take a short look at some rough ideas what

### a soft rubber belt without additions

This is usually a bad choice for printers, but can occasionally be in very cheap kits. This kind of belt *has* applications. It is for really low loads, it can work tight bends for a long time and provides superb self-tensioning with just a very short tensioning device. On the other side, most rubbers don't take heat well, stretches a lot, wear fast and can only move a light load. If it rubs against a standing object, it squeaks horribly.

### a medium hard, somewhat elastic belt reinforced with fibers

The standard belt we often get with printer kits. the fibers lessen the material's stretching ability while offering still some self-tensioning (depending on the fibers). These properties allow to move medium loads yet harder material demands slightly larger bend diameters (not *too* much, but measurable!). When the piece gets friction against a standing surface the sound will be not that horrible, but the harder rubber might start to shave off, break teeth and destroy the belt after some time. The typical reinforcing is done with cloth, usually cotton, so there are some limits to how much they can take.

### reinforcing with aramid fibers

Some fibers are better than others for our applications because of how they stretch and reinforce it. Aramid fibers, for example, are better than cloth. Some *consider* them as impossible to wear out with the tension in 3D Printing applications alone, but that is not entirely the case. They still stretch under larger loads or on longer lengths enough that it can be a problem (or become one). They also can still be shredded with friction (and heat). For a professional machine, the expected lifetime is quite nice. They are though, but only as good as the rubber used and if properly installed. There are also generally two types: long fibers and short fibers. Long fibers have a somewhat even stretching behavior, while short fibers have totally different stretching behavior. The latter type is looked at in scholarly articles like [Yin, Zhou, Lou et al.](https://www.sciencedirect.com/science/article/pii/S0142941819307160)

### a hard belt reinforced with fibers

Let's take... Uhm... a toothed belt from a car. I believe some of these are aramid-reinforced, old ones are on cloth cores, most modern ones I know are steel reinforced. It is somewhat hard. By design, it is made to withstand a strong tension at high speeds. It needs somewhat big bending radii for the hard rubber, but that is easily given by the gears and the large teeth don't break easily. Over the lifetime it will slowly stretch due to the temperature it will encounter, till at some point it gets too loose or looses too many teeth as the parameters don't match up with the teeth anymore and they get ground away. It is made to deliver high torque and could move - if something similar was used on a printer-like machine (like a large CNC), a heavy load for a long time, but the machine needs to be made accordingly.

### steel reinforced belt

Steel is going stiffer. Steel reinforcements usually get the stretching parameter to a bare minimum at the cost of increasing their minimum bend and added weight. They can be used to move very heavy loads without the belt starting to slack as it simply can't stretch to give slack on the underside of the belt loop when forces are applied. Steel belts are pretty much Heavy Duty. If you can work with the bending radii belonging to them (as said, usually a little bigger than a similar fiber-reinforced one), you could make use of these properties, for example in a CNC Router with a full spindle or when moving very heavy tool heads.

### carbonfiber reinforced

And then there is the super heavy-duty carbon fiber. One can barely stretch it (steel is less stretchy), making these belts super tough in the stretching compartment and granting an extremely long life under most conditions. In comparison to steel, they can work much tighter radii. Usually, they are coupled with urethanes to get a high wear resistance against abrasion. The biggest downside: their price.

Belt Materials

--------------

### Silicone

Silicone is soft but high temperature resistant but dislikes abrasive forces.

### Uretane

Urethanes are not the best to handle the heat, but they can handle abrasive forces. They also don't create dust in the same way as other rubbers.

### Neoprene

The most interesting feature of neoprene belts is their reduced noise under work.

Upvotes: 3 <issue_comment>username_4: I have recently changed the standard belts on my Prusa MK3 for the aramid fiber reinforced E3D neoprene belts. Those belts are really tough and hard to cut even with a quality side cutter! They have a much smoother surface and a lot more aramid fibers than the standard belts.

Prior to the change, the belt on the X axis was twisting when changing directions, now it is running straight and smooth. Surface quality has improved a little, the ripples are smaller and more regular. Overall a small but noticeable improvement

P.S. I am using belt tensioners on both x and y axis.

Upvotes: 2 <issue_comment>username_5: I had really bad problems with GT2 PU belts (including steel reinforced), under big tension they degrade suddenly with big change in the geometry at some position. When removed they look twisted. Looks like some reinforcing wires slipped inside the PU body of the belt.

Once switched to rubber GT2 belts (fibreglass reinforced) I never had problems connected to the belts. I can tell that rubber GT2 belts have no noticeable change in the geometry over many years of constant use under high tension with the spring.

Upvotes: 0

|

2018/08/23

| 541

| 2,206

|

<issue_start>username_0: So apparently the wiring in my home is... questionable. Very rarely, plugging or unplugging things will cause a power dip. This is almost always the result of turning on a fan or something, is only for a moment before coming back, but its long enough to cause my printer to reset. I want to add a backup battery supply using either the 12v cell pulled out of an old apc ups (before the suggestion of just plugging it into that... I did, somethings fried in it and it will ALSO power cycle everything connected to it every few hours) or an old car battery. Is there any reason I shouldn't use this circuit, which was originally intended for amateur radio equipment? [](https://i.stack.imgur.com/Jd7Sp.gif)

Also is there anything else i should be considering?<issue_comment>username_1: This circuit is correct as it does the job (provides a charge and switch-over when needed).

The only drawback could be that you need to ensure that the battery is sealed as during the charging process the electlorit will slowly evaporate and decrease battery capacity.

I am personally using a UPC as that gives me more options to power-up more stuff including 240V heater and it has a self-test built-in (it is APC1500VA).

Upvotes: 2 <issue_comment>username_2: There are a couple of points to consider with this question. First, you will need to make sure the PSU is correctly adjusted to the float charge voltage of the 12V battery. SLA should be safe to float charge, but over voltage will damage it over time.

One alternative solution (since powering the heaters will limit your run time) is to detect power failure, cut the heaters immediately, and save state to EEPROM in the firmware. This is the approach taken in the latest Prusa printers, and is a bit more complex, but might turn out to be more reliable.

If the problem you are solving really is brown-outs, then a simpler solution might be to isolate the high current and control sides of the circuit. The MCU will be run from a regulated 5V or 3V3, so a large capacitor (with diode isolation) on that regulator's input would do the trick.

Upvotes: 3 [selected_answer]

|

2018/08/23

| 1,409

| 5,555

|

<issue_start>username_0: I have an Ender 3 which I primarily use for printing with PLA. I haven't branched out to other materials yet. :)

I've done [some research into PLA fumes and airborne particulates](https://3dprinthq.com/desktop-3d-printer-safety/) which seemed to mention that PLA is mostly safe, but ABS is rather dangerous to print without proper ventilation. However, I understand that there isn't much research on the topic and that there haven't been many studies.

I have been keeping my printer in my bedroom, far isolated from flammable materials, which I sometimes leave on to print while I'm asleep. Should I be concerned with my health safety with respect to airborne particulates emitted by printing with PLA?

**Other questions ask about ABS, but here, I'm asking specifically about PLA.**<issue_comment>username_1: Fire is the most obvious risk - firmware can now detect some of the more obvious failure modes such as a detached thermistor, but loose or failing connections can still overheat. A smoke alarm is a fairly obvious (but not necessarily effective) protective measure.

The risk from particulates in particular is *probably* low, but marginal health risks like this are extremely hard to analyse, and will likely take many years to manifest. The closest analogue would be to look at commercial plastics workers since they are exposed to both heated plastic, and any potential dust generated.

You could also compare the risk to other 'hobby' activities such as soldering, painting, woodworking.

Upvotes: 5 [selected_answer]<issue_comment>username_2: Standard manufacturing practices contraindicate leaving a manufacturing device unmonitored while it's on. That being said, your workshop should be well ventilated anyways since you're probably using acetone, isopropyl alcohol, and other substances that you shouldn't inhale.

If you can not move to a well ventilated workshop, consider installing a fume hood or at least a range hood in your current workshop

Upvotes: 0 <issue_comment>username_3: **You are probably pretty safe printing PLA**

1. Regarding emissions, the following recent report, [Emissions of Ultrafine Particles and Volatile Organic Compounds

from Commercially Available Desktop Three-Dimensional Printers

with Multiple Filaments](https://pubs.acs.org/doi/pdfplus/10.1021/acs.est.5b04983), indicates that PLA is a pretty low emitter (1/20th of nylon) and most of what it out-gasses is Lactide which is low on the harm scale. That said, everybody's nose sees things a bit different and people tolerate smells differently. Note also that we used to think lots of things (like asbestos) were harmless that we know differently now. Note also in the figure below from the [report](https://pubs.acs.org/doi/pdfplus/10.1021/acs.est.5b04983) that all PLAs are not created equal. Dremel PLA produce way more nasty stuff than FlashForge PLA did. I am also sure additives, colorant, and fillers can change this a lot as PLA filaments aren't not all PLA.

[](https://i.stack.imgur.com/oFK7Y.jpg "Estimates of emission rates for the top three highest-concentration VOCs")

2. Regarding the fire safety issue. Note that there is a BIG difference between a kit and a "product". Since you are the manufacturer of the printer for a "kit", the packager of the "kit" is not responsible for the fire or electrical certifications of the final product. This does open the door to some risks. The biggest risks are electrical safety; but, fire safety can be an issue as well. I would say that the risk is likely higher to you personally when the printer is NOT in your bedroom as if it catches fire when you are sleeping, you will likely catch the fire faster if it is in your bedroom.

3. From a practical standpoint, I have heard several people complain that they can't sleep when the printer is printing when the printer is in a separate room.

Upvotes: 4 <issue_comment>username_4: I have been printing daily for 2 months with PLA and have noticed respiratory problems! I feel like slight pneumonia symptoms!

I also have very sensitive lungs that react to things that would not bother normal people.

Upvotes: 3 <issue_comment>username_5: Having asthma, I'm very sensitive to air quality and when i first started 3D printing i quickly noticed a sore throat, feeling out of breath, headaches and well the smell.

One thing many beginners overlook is material oozing out of the extruder in places other than the nozzle itself. This causes a dirty extruder head which 'burns' that material and thus creating a ton of air pollution and a nasty smell.

As a fix, i took my extruder head apart and reassembled it with PTFE tape on all the threads. The oozing and burned smell of material is now completely gone, my initial health issues have also gone away.

This does not take away the fact that ultrafine particles are still being generated, but you will not notice this problem in an acute way. If you print daily use a fume extractor, your lungs cannot clean out this size of particles. The health effects will be similar as living near a busy street or highway.

One last thing few people mention: cleaning up parts. When you file or sand down parts this creates a lot of very fine dust, and since plastics are electrostatic this becomes very hard to clean up. I now use an extraction fan whenever I'm cleaning up a printed part.

Upvotes: 2

|

2018/08/23

| 1,675

| 6,601

|

<issue_start>username_0: I've seen many references to a FDM print being weakest in the Z axis, due to poor bonding between layers compared to the extruded walls.

Thinking about optimising this for a specific material (excluding temperature and geometry), is there an optimum layer height? It seems obvious that too thick a layer will give less compression and maybe less heat transfer into the layer below (so 0.3 with a 0.4mm nozzle might be expected to be a bit weak). Is there a single break point (i.e. less than half the nozzle is good), or are super fine layers either good or bad?

I'm specifically using PLA at the moment, in case different materials have different behaviour in this respect.

I am **not** asking how to model the strength of layer bonds or how to take that into account when designing a part.<issue_comment>username_1: My3dmatter.com performed a [series of tests](http://my3dmatter.com/influence-infill-layer-height-pattern//influence-infill-layer-height-pattern/) with PLA, using "a universal testing machine". They conclude:

>

> Layer height influences the strength of a printed part when it becomes

> thin. A printed part at 0.1mm shows a max stress of only 29MPa, as

> opposed to 35MPa for 0.2mm (21% increase).

>

>

> Past 0.2mm, the max stress remains fairly constant around 36 MPa (we

> confirmed this conclusion with an extra test at 0.4mm, not shown here

> because it was not part of the same batch).

>

>

>

[](https://i.stack.imgur.com/i2fXm.png)

Note: It is recommended to read the full article to comprehend the complexity of the subject matter.

Upvotes: 4 [selected_answer]<issue_comment>username_2: According to the people of Ultimaker, the best layer height for PLA is [50% of the diameter of the nozzle](https://community.ultimaker.com/topic/22969-layer-resolution-range/?tab=comments#comment-209869). They did extensive testing, although they have not, as far as I'm aware, released any research papers or numbers gathered from their testing.

So, if you have a 0.4mm nozzle, keep your layers at 0.2mm height for best bonding, 0.4mm for a 0.8mm nozzle, and so on.

The max ratio possible is 75% of nozzle diameter, though, at this point, your print has the consistency of a spider web. I tried with a 0.4mm nozzle and 0.3mm layer height and nearly crushed the test print when taking it off the print bed. Anything above that and you end up with the dreaded spaghetti plate.

(Note: I own an Ultimaker 3 Extended, thus why I asked them when I was doing some tests.)

Upvotes: 2 <issue_comment>username_3: The question is not easy to answer as it would be difficult to give exact print guidelines. [This answer from user @username_1](https://3dprinting.stackexchange.com/a/6733/5740) already shows results of the print height versus the specimen strength (IMHO his answer should be the accepted answer), as taken from [this excellent reference at 3DMatter](http://my3dmatter.com/influence-infill-layer-height-pattern/) which basically describes the results of a series of experiments. This answer builds upon his answer. In reference to your question, this reference did not optimize the print settings (all specimens are made with the same print settings), so your question is valid.

It is assumed that you imply in your question that all print parameters that effect the inter-layer bond strength needs to be taken into account for the optimization. Many parameters are in play to bond the filament onto the previous layer, amongst these parameters are e.g.:

* Print speed

* Filament temperature

* Print height

* Print cooling

All these parameters influence the deposition temperature which in its turn determines the bonding to the previous layer. Not only printer parameters play a role here, but also the properties of the material itself. Between the various brands, and even within a single brand, material variations (e.g. color doping, or different process batches) influence these parameters.

The question states

>

> It seems obvious that too thick a layer will give less compression and maybe less heat transfer into the layer below

>

>

>

Well, this is not so obvious and assumes that compression is the main driver for bonding a layer. However, the larger the layer height, the more filament can be deposited at once with a higher heat capacity (stays hot longer), so potentially this could have a positive influence on the bond (higher temperature, better adhesion).

The print fan cooling parameter could play a very important role here (or even the filament print temperature). In fact, the results of this are already shown by the 3DMatter experiment referenced above. If you keep all print parameters the same except for layer height, the bond strength increases. This implies that in order to get a better bond for low print heights, you should decrease the amount of print-fan cooling flow, or increase the filament print temperature. How much this is should be done in a similar experiment where you lower the cooling air and increase filament print temperature for more specimens (separately) and test again. This is referred to as a [design of experiments](https://en.wikipedia.org/wiki/Design_of_experiments).

Theoretically, you can make the bond at any layer height just as good provided you optimize the correct parameters. This implies that there is no relation between the print height and the bond strength, it is just a matter of proper setup.

Also, I would not say that poor bonding strength is the cause of failure in Z direction, as FDM deposits layers in between each layer you will have a lot of potential crack initiation locations, this is usually the starting point of the failure. I have seen prints start the failure between the layers, but not continue to crack along the layers, but traversing through the layers meaning that the bonding strength is not that bad after all.

[](https://i.stack.imgur.com/WCQnm.png)

Upvotes: 2 <issue_comment>username_4: Just adding another datapoint. CNCKitchen has a new [video](https://youtu.be/fbSQvJJjw2Q) where he analyses this for cross layer and between layer tension. He also references some other research (which is rather inconclusive). He supports the coarse estimate of 'no more than 50% of the nozzle diameter, with performance also dropping at very low layer height.

He found cross layer tension supported more than 2x the layer-to-layer tension (with a typical 3-wall, low infill pattern).

Upvotes: 1

|

2018/08/23

| 2,750

| 9,128

|

<issue_start>username_0: I will be creating a small tube styled piece to use as a junction between two pieces of plastic. The idea is to reattach the two pieces and provide strength so they don't break apart again. I plan on using PLA.

My question is, will superglue (cyanoacrylate) work best for this or are there better choices for attaching PLA to hard (injected molded) plastic? The big thing I'm wanting to make sure is if any of these glues will dissolve the PLA and whether some glues might bond better than others.<issue_comment>username_1: Yes Super Glue is best choice.

I personally use it in many PLA projects.

I even apply Super Glue layer to ABS prints to avoid layer separation.

It works well with both ABS and PLA, but exercise some caution whilst using Super Glue because it produces very bad tear gas. Use it in a well ventilated area.

Upvotes: 3 <issue_comment>username_2: PLA is a nice one, and gluing has been a topic on some of our most favorite maker's channels. For example Stefan from CNC kitchen ([this video](https://www.youtube.com/watch?v=JSff8OMRHtw)) and Joel the 3DPrinting Nerd ([this video](https://www.youtube.com/watch?v=s1q2D_pK0BE)). Also, in 2022, [Tom's 3D](https://youtu.be/dGE509zjf7E) ran a test on glues for PLA, PETG and resin prints. Here some information from them together with my own experiences. Most of these glues are not exactly PLA specific by the way and work for many other materials too. Be careful with PLA containing infil though, as that can seriously alter the properties.

Step 0: Safety First!

---------------------

Some of these methods are working with chemicals that can irritate the skin (resin, cyanoacrylate), have irritating fumes (acetone), or are flammable (acetone). Others (Cyanoacrylate) are not heat-stable and break down into their components under heat.

### Use proper protection when working with glue! Eye protection and respiratory protection, as well as gloves, are to be used when necessary. Read the manual of the products you are working with!

Preparations

------------

For most glues, it is advisable to prepare the surface: sand it to increase the surface area, remove grease from fingerprints etc. Follow the manual!

Glues

-----

* Cyanoacrylate - yep, the "one kind for all" is a solution for PLA too: Superglue. However, look out for what type you get! Some are clearly better than others, and using an accelerator can change the properties of the glue spot.

+ Together with talcum powder, CA glue ("superglue") can fill gaps easily. However, a gap-bridging bond isn't the strongest, and working can be finicky. Yet if the parts do sit flush, a CA glue bond can be a almost as strong as any 2-component glue bond tested, according to Tom.

+ **CA is not stable under heating and when heated too much it breaks apart into a rather noxious fume!** This can be handy to break metal-CA-metal bonds in machining of small parts but keep this in mind if you want to use inserts or plastic-soler pieces on the same areas! Don't tack with CA in those cases.

* Epoxy resin - Epoxy is a favorite for very tough gluing, a few droplets can stick a car to the roof... and it warms up in curing. If you take a slow

curing resin, you can safely use it to glue PLA without the part deforming.

+ **Uncured Resin and their hardeners are strong skin irritants.**

* 2-Component Acrylic resin is just as good as epoxy often, as Tom noticed. It's very comparable to Epoxy in performance.

* [Urethanes](http://www.adhesives.org/adhesives-sealants/adhesives-sealants-overview/adhesive-technologies/chemically-curing/two-component-(2-c)/urethane-adhesives) - 2 Component Urethanes offer strong but flexible bonds and work great according to Joel. Their curing process is also exothermic, so take care to not 'cook' your piece.

* 2-phase Putty - in a similar vein come 2-phase putties like [Green Stuff](https://www.games-workshop.com/en-FI/Green-Stuff) or [Miliputt](https://www.milliput.com/), which harden after mixing. Their heat generation isn't too big and they allow to fill gaps easily. My favorite stuff though is not the expensive modeling putty but the stuff from the home depot: stuff like [Pattex Repair](http://www.pattex.de/do-it-yourself-mit-pattex-klebstoffe-produkte-new/pattex-klebstoffe/reparaturkleber/repair-express.html)sorry, no English site for this or [UHU Repair All Powerkitt](http://www.uhu.com/en/products/epoxy-adhesives-2-component/detail/uhu-repair-all-powerkitt-1.html?cHash=e0f929a3ec974e591e89c5e1987a30ab&step=70) harden within an hour, are surprisingly cheap and get a smooth surface.

* Acetone - We all know that you can smooth and glue ABS with Acetone or an acetone-ABS slurry. [Tom (<NAME>)](https://www.youtube.com/watch?v=VZUfq0yrtv4) made a few experiments with it. He discovered that it works for at least *some* types of PLA in the following fashion: apply some acetone to a spot and press the second piece (that also was prepared this way) to it and they might melt themselves together after some time.

+ Effectivity of this depends **very highly** on the exact PLA you got.

+ **Acetone is highly flammable.**

* There's a type of glues commonly called "Kraftkleber" or "Alleskleber" in Germany, for example, [UHU Hart](http://www.uhu.com/en/products/special-adhesives/detail/uhu-hart-kunststoff-1.html?cHash=9e818145273de580c4e3c132faad3710&step=202) or [Pattex Kraftkleber](http://www.pattex.de/do-it-yourself-mit-pattex-klebstoffe-produkte-new/pattex-klebstoffe/kontaktkleber-gel-fuer-schwierige-oberflaechen/kraftkleber-transparent.html)German. While they often *stick* to PLA, I personally don't like their gluing power and find them often quite messy to work with. Also, they very much fail in loadbearing joints.

* Wood Glue - Yes, Wood Glue. PVA Wood glue as well as its non-water-soluble cousin ("Express") have proven themselves to me as a rather nice surface coating to smooth over print lines as well as a good solution to affix paper and wood to prints. It is less of a solution for plastic-plastic bonds but works OK-ish.

Glue? Why glue?!

----------------

### "Solder"

What better way is there to combine parts than welding or soldering?! Often none. My personal all-time-favorite PLA *glue* is PLA itself, by using it as **PLA solder**. This method also works for most other filament types, but is not advisable for ABS and other plastics that emit fumes without wearing respiratory protection! In any case, you need to work with an exhaust, as you heat your plastic in a not always fully controllable way. If you can, use a soldering station where you can set the temperature of the iron.

* Take the pieces and make sure on both sides is a cavity that can be filled.

* Take a soldering iron and set it to around 200°C.

* Take a length of PLA filament.

* Melt the filament with the soldering iron and use it as solder when combining the two pieces. Make sure that at least some filament gets into the cavities and sticks there - it can help to stick the soldering iron into the goop in there to force it to merge with the infill/walls and press together to hot PLA goop filled pieces against the iron before pulling it away, pressing the pieces together.

* As the PLA cools and hardens, the joint is usually tougher than the actual layer boundaries.

### Pen

Instead of using a soldering iron, one might also use a 3D printing penOne that eats filament, not one for PCL or some gel!, but I don't like those personally.

### Inserts!

On a different note, a soldering iron is also a very good solution to make inserts into PLA - heat up the metal insert (like a nut) and press it into an undersized hole, and it will mold the plastic around itself into a perfect fit without any glue.

### Friction Welding

An alternative to using direct heat from a soldering iron is **friction welding**. For this, take a rotary power tool and some filament. Insert the filament into the tool, tighten and cut so that about an inch is reaching out of the claw. Turn it on at medium speed, about 800 to 1200 RPM. Now, once you press the tip of the spinning filament against other PLA it gets hot and melts, creating a welding seam. [Joel](https://www.youtube.com/watch?v=Pa2DoE3sirU) has a good explanation.

Upvotes: 6 [selected_answer]<issue_comment>username_3: I used to work at a small thermoforming plastics enclosure company and we used “weld-on” for basically ANYTHING. Delrin and medical grade plastics not included but, PC, PE, acrylic, PETG, etc. use "weld-on number 3" for more easy bond plastic, "number 4" for more crystalline/harder to bond plastics.

Upvotes: 2 <issue_comment>username_4: [PLA Gloop](https://www.3dgloop.com/shop/pla-gloop) is dedicated glue for PLA. It contains chloroform, so be careful.

* [3D Gloop! // 3D Printing Adhesive Spotlight](https://www.youtube.com/watch?v=gTtW_NXFMCY)

* [PLA Smoothing 3D Prints with 3D Gloop!](https://www.youtube.com/watch?v=vQc5TBPF8uw)

Additionally a PrusaPrinters guide: [The Great Guide to Gluing and Assembling 3D Prints](https://blog.prusaprinters.org/the-great-guide-to-gluing-and-assembling-3d-prints_44908/)

Upvotes: 1

|

2018/08/23

| 4,154

| 16,035

|

<issue_start>username_0: What are the 'headline' basic design rules for FDM?

Which topics for design principles do you recommend to someone who has purchased an FDM machine and wants to understand what is practical? In other words, where is the place to start when you don't yet know what questions to ask?

[This question](https://3dprinting.stackexchange.com/questions/5215/3d-printing-references-for-beginner) and its answer discuss design tools and the workflow but doesn't cover design rules.

Design rules here meaning the principles of what is **special** about **planning** a design to be manufactured with an FDM process as opposed to traditional machining or a printing process like SLA, not the detailed/automated checks that would be applied to something like a PCB layout prior to sign-off.<issue_comment>username_1: Designing a part for 3D printing often doesn't seem to have many special considerations, but I have learned the hard way, that there are some things to do differently. This is just a list of things to that one should keep in mind ***in addition to basic principles of design***1 when designing parts, keeping the subsequently slicing the parts in mind too:

Print orientation

=================